Laser Cut Blanks

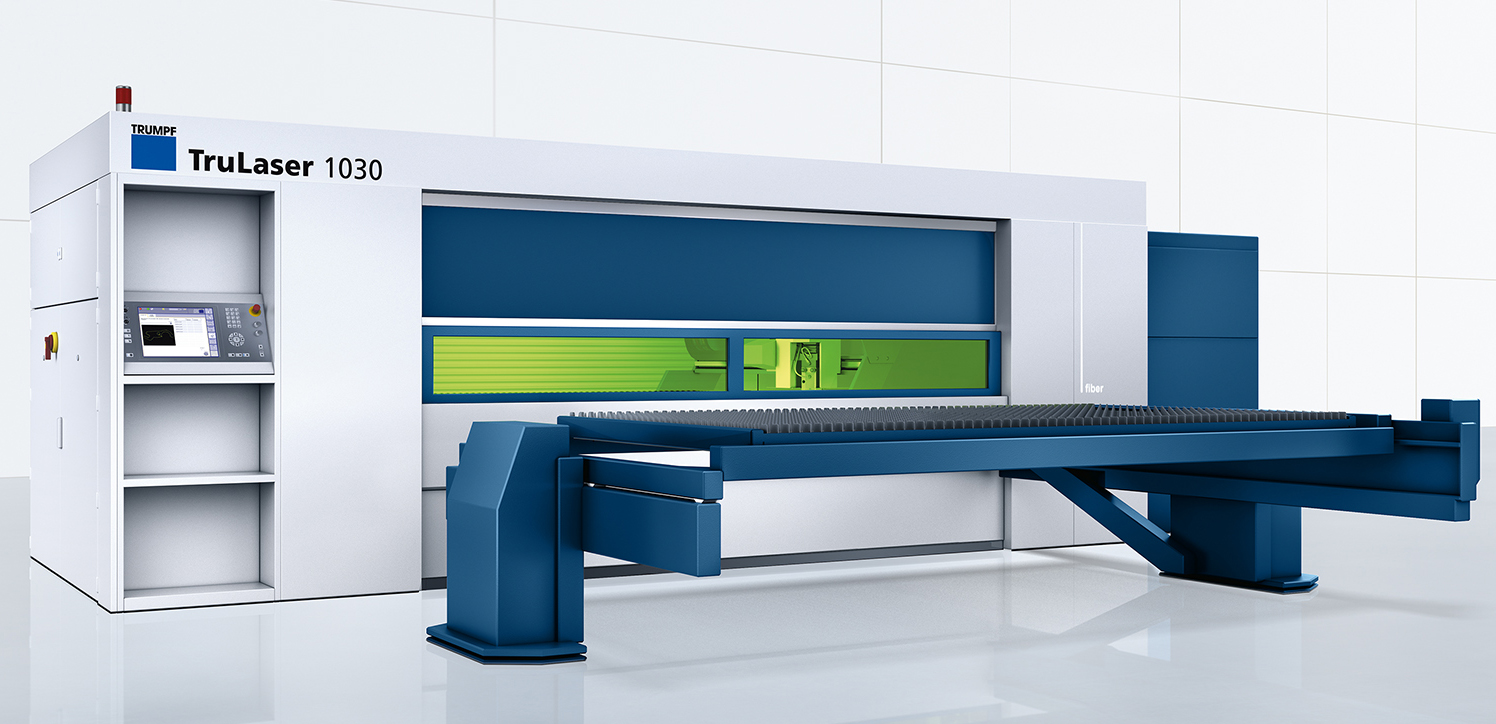

In an effort to provide more value to our customers, we have a 3-axis Fiber Laser, which give us the ability to provide any shape that customer may require. Historically, to yield finished parts, our customers had to source material and laser cutting separately. We have combined those and can provide a finished part, at one-price, all under one roof.

The advantages of this include:

One Stop Shop

You no longer have to source material and processing separately.

By eliminating additional steps, you eliminate potential issues.

You provide us with the material spec and dimensions and we will provide you with a finished piece.

By eliminating a step in the process, we can insure quicker delivery and guarantee quality.

By eliminating additional steps, you eliminate potential issues.

You provide us with the material spec and dimensions and we will provide you with a finished piece.

By eliminating a step in the process, we can insure quicker delivery and guarantee quality.

Cost Savings

No need to purchase additional material that may not be necessary.

Reduced freight charges by cutting out delivery to a processor.

No Scrap.

More efficient use of your equipment/time. No longer have to use your 5-axis machines for flat parts.

Reduced freight charges by cutting out delivery to a processor.

No Scrap.

More efficient use of your equipment/time. No longer have to use your 5-axis machines for flat parts.

Space Savings

We become your warehouse.

No more obsolete material from past jobs taking up valuable floor space.

You order exactly what you need, no more…no less.

Easy re-order for repeating jobs.

No more obsolete material from past jobs taking up valuable floor space.

You order exactly what you need, no more…no less.

Easy re-order for repeating jobs.